Case Study: Atlas Asphalt Batch Mix Plant 3D Explainer Video

Introduction: Atlas Asphalt Batch Mix Plant

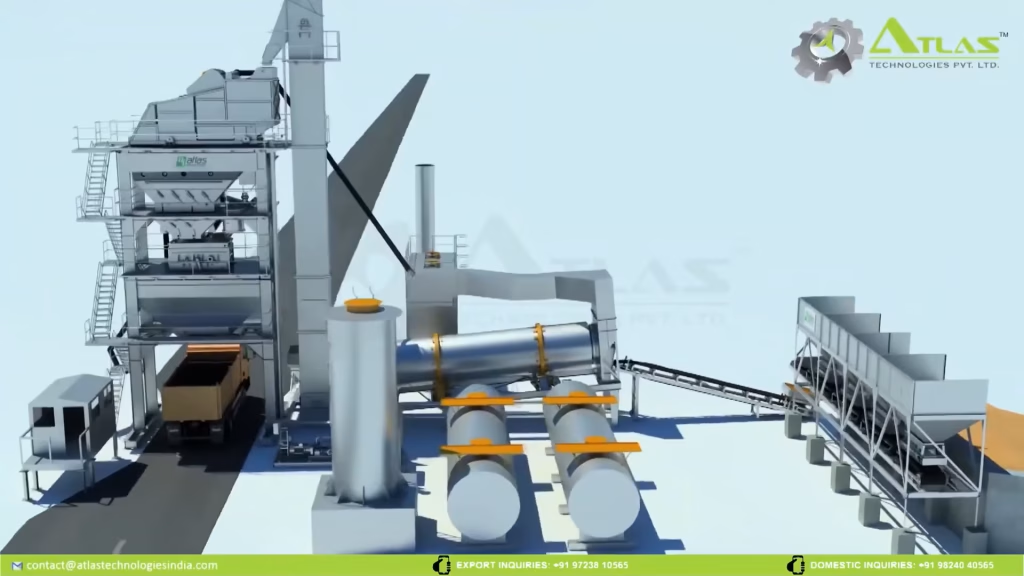

In this Atlas Asphalt Batch Mix Plant 3D Explainer Video case study, we created a 3D explainer video of how to create batch mix plant aka asphalt concrete – a crucial material for constructing durable, smooth, and long-lasting road surfaces. Through engaging visuals and eye-catching motions, we covered the plant’s cutting-edge features—including multi-stage aggregate processing, pollution control technology, and high-speed mixing arms, etc. Overall, asphalt batch mix plant case study serves the full 3d explainer video of Atlas Asphalt Batch Mix Plant manufacturing process.

Client Video

Highlights

–>Atlas Technologies leads in manufacturing innovative asphalt batch mix plants.

–>The plant uses a multi-stage drying drum for efficient aggregate heating.

–>Advanced pollution control units ensure dust collection and clean air release.

–>Reverse airflow cleaning maintains the efficiency of the bag filter system.

–>Vibrating screen system sorts aggregates by size for precise batching.

–>Accurate weighing of aggregates, bitumen, and dust ensures consistent asphalt quality.

–>Final asphalt mixture is stored in silos and ready for immediate road application.

Summary:

Credit: Chasing Illusions

The video from Atlas Technologies provides a comprehensive overview of their advanced asphalt batch mix plant, highlighting the innovative systems employed to produce high-quality asphalt efficiently.

The plant’s process begins with the cold aggregate feeder, where raw materials are loaded into bins and transported via conveyor belts to the vibro feeder system. The drying drum, divided into three sections—conditioning, combustion, and discharge—heats the aggregates quickly and uniformly.

To maintain environmental standards, a sophisticated pollution control unit captures dust particles using a pre-separator and bag filter system, which utilizes reverse airflow cleaning to maintain efficiency. Dust collected is stored in dedicated hoppers.

Hot aggregates are then elevated to a vibrating screen system, which sorts them by size into hot bins. These bins are equipped with radio gates that feed aggregates into weighing hoppers according to precise recipes for batch creation.

Simultaneously, bitumen and dust are weighed and added to the mixer, where specialized agitating arms ensure thorough and rapid blending, coating mineral surfaces with bitumen evenly. The resulting asphalt mixture is stored in silos, ready for loading onto trucks for road laying. Atlas emphasizes the plant’s ability to produce fresh, top-quality asphalt efficiently.

Client Overview

Name: Atlas Technologies PVT. LTD.

Industry: Manufacturer and Exporter of Asphalt Batch Mix Plant

About: Atlas Technologies Pvt. Ltd., founded in 2014 and based in Mehsana, Gujarat, is a prominent manufacturer, exporter, and supplier of road and civil construction machinery, specializing in high-quality equipment for road contractors at reasonable rates.

The company offers a comprehensive product range including asphalt batching plants, concrete plants, bitumen sprayers, and drum decanters, serving both Indian and global markets with exports accounting for up to 20% of turnover. With a workforce of approximately 201-500 employees and an annual turnover between ₹25 crore and ₹100 crore, Atlas Technologies operates from a 10,329 square foot facility and prioritizes modern infrastructure, strong after-sales support, and innovative, cost-effective solutions to help clients complete projects efficiently and profitably.

Why Choose Us

Atlas company chose Chasing Illusions Studio as one of the best 3D industrial machinery walkthrough video companies in India for a complete guide of “Atlas Asphalt Batch Mix Plant Manufacturing process” because we – Chasing Illusions Studio is specialized into converting Industrial Plant Walkthroughs to engaging Mechanisms Animations with easy-to-understand and eye-catching 3d visuals.

With over 15+ years of expertise and a team of 80+ skilled animators, we ensure every stage of the plant’s process—from material input to final asphalt output—is illustrated with precision and realism. Our videos not only educate stakeholders and clients about the technology but also serve as powerful promotional tools that highlight efficiency, innovation, and reliability.

In this context, our industrial animation maker and technical experts collaborate closely with engineers, manufacturers, and industry professionals to ensure the absolute accuracy and functional representation of your operations to turn technical concepts into compelling stories that drive results.

By choosing us, Atlas can showcase its manufacturing excellence in a way that captivates audiences and builds stronger trust in its brand.

Client Challenge

The client needed to introduce their unique machine to both B2B customers and distributors in a visually impactful way. Traditional brochures and product photos couldn’t adequately demonstrate how the machine worked or highlight its ease of use and technological precision. They needed a short, engaging video that could:

–>Clearly demonstrate functionality

–>Appeal to non-technical viewers

–>Be used across marketing channels

That’s why industries like Atlas company were looking to upgrade themselves and connect with advanced technology and the best animation production company to create “Atlas Asphalt Batching Machinery Plant Walkthrough” , a complete guide on how to create asphalt batch mixing plant. In this context, company faced several challenges like accurate representation of the plant’s intricate machinery and the step-by-step mixing process in a visually clear and precise manner.

Additionally, they must ensure the video effectively communicates the plant’s unique features and benefits to a global audience, balancing technical detail for engineers with a more accessible message for sales teams and potential clients.

Most important, striking the right balance between technical details and easy-to-understand visuals—something that not every animation production company can deliver effectively.

Our Process

Credit: Chasing Illusions

Our process began with an initial discussion to understand the script that includes information about the plant’s workflow, machinery, and key functions like Cold aggregate feeder, Vibro feeder system, Hot aggregates, Weighing Hoppers, Pollution Control unit, Bitumen and Dust Weighing System, etc.

Our team then creates precise 3D models of the entire plant, including its internal components and the raw materials used. The animation process focuses on visually demonstrating the step-by-step manufacturing process—from material feeding and drying to mixing and asphalt discharge.

Finally, we integrate clear on-screen text, technical labels, and a professional voiceover to effectively communicate the process and the plant’s unique selling points to a B2B audience.

Solution

Credit: Chasing Illusions

As per Atlas Technologies’s requirement, we delivered a 6:31 minute video that was technically accurate yet visually engaging 3D animation that showcased the entire asphalt batch mix plant manufacturing process in a step-by-step manner.

We transformed complex mechanical operations—such as material feeding, heating, mixing, and final output—into clear, easy-to-follow visuals. By incorporating realistic 3D modeling (to accurately represent the entire plant, from the raw material feeders to the final asphalt mixer and silo.), dynamic camera movements, and simplified explanations, we created a video that not only demonstrates the plant’s efficiency but also serves as a powerful marketing and training asset for Atlas.

The solution bridged the gap between technical detail and audience-friendly storytelling, making the manufacturing process both informative and compelling.

Results

Atlas’s decision to trust in Chasing Illusions Studio for Atlas Asphalt Batch Mix Plant 3D Explainer Video brought significant results:

Credit: Chasing Illusions

Simplified Technical Communication (50% Faster Learning)

The video broke down the complex asphalt batch mix process into easy-to-understand visuals, reducing training and explanation time by nearly 50% compared to traditional manuals and presentations.

Increased Client Engagement (45% Higher Retention)

By using realistic 3D animations, dynamic visuals, and smooth storytelling, the explainer achieved 45% higher viewer retention, keeping clients engaged throughout the entire process demonstration.

Enhanced Marketing Impact (30% Boost in Inquiries)

The promotional use of the video on websites and trade shows helped Atlas attract more potential buyers, contributing to a 30% increase in product-related inquiries and discussions.

Versatile Training Asset (100% Reusable Across Teams)

The animation was designed to be fully reusable for training operators, engineers, and sales teams, saving costs on repeated training sessions and ensuring consistent communication.

Improved Brand Positioning (25% Stronger Recall)

With a professional and visually striking video, Atlas established itself as an innovative leader in asphalt plant manufacturing, achieving a 25% improvement in brand recall among industry stakeholders.

Conclusion: Atlas Asphalt Batch Mix Plant

The “3D animation video of Asphalt Batch Mixing Plant” by Chasing Illusions Studio proved to be a powerful tool for both education and promotion.

Credit: Chasing Illusions

By simplifying complex operations, the video enabled 50% faster learning for training purposes and achieved 45% higher viewer retention among clients. Its use in marketing generated a 30% increase in inquiries, while its 100% reusability across teams ensured long-term cost savings.

Most importantly, it strengthened Atlas’s brand identity, delivering a 25% improvement in brand recall within the construction and manufacturing sector. With this project, we once again showcased our ability to blend technical precision with creative storytelling, driving measurable impact for industrial clients.

FAQs – Atlas Asphalt Batch Mix Plant

How does a 3D explainer video help in showcasing the Asphalt Batch Mix Plant process?

A 3D explainer video visually demonstrates each stage of the plant’s operation—such as material feeding, heating, mixing, and final output—making it easy for clients, engineers, and operators to understand the process in a clear and engaging way.

Can the video be used for both training and marketing purposes?

Yes. The video is designed to be versatile—it serves as a training asset for plant operators and engineers while also acting as a promotional tool at trade shows, websites, and client presentations. This dual-purpose approach ensures maximum ROI.

What measurable benefits did Atlas gain from this 3D animation?

The video delivered significant results, including 50% faster learning in training sessions, a 30% boost in client inquiries, and a 25% increase in brand recall—helping Atlas strengthen both its operational efficiency and market presence.

How to contact Chasing Illusions Studio for 3D Industrial Explainer Video?

You can contact us via official websites: chasingillusions.com, chasingillusions.in, email: info@chasingillusions.in, contact us page, or even WhatsApp for faster responses in hours.

Here’s Atlas’s feedback for the video:

“Chasing Illusions Studio transformed our complex batch mix plant process into a clear and engaging 3D video. Their work not only improved client understanding but also boosted our brand presence and inquiries. Truly a professional team to work with.”

CONTACT NOW

For faster response conatct on WhatsApp